Has anyone experimented with building bell shaped hoods for the end of collection pipes or the connection inside cabinets?

Bill Pentz refers to using these in the section of his website on Tool Ducting under Dust hoods. At the Australian Woodwork Forum, there is a very active section on dust collection and one member, Bob Loss (BobL), posts extensively about improving dust ports and the connections to our machines. He is a big advocate of using bell shaped hoods to improve air flow for fine dust collection by as much as 20%. His principle thread on the topic where he discusses the four typical connections into a machine cabinet and then shows how to create bell shaped hoods in both 4" and 6" PVC pipe using a mold is here:

Improving machine cabinet dust ports

And the post within that thread where he shows his molding process is here:

Creating Bell Shaped Ports with a Mould

Two examples of the dust flow created with a bell mouth hood are illustrated by the sawdust flowing off of the wood being sanding in these two videos:

https://www.youtube.com/watch?v=xMlX1wavcWs

https://www.youtube.com/watch?v=xjtHCmR-N3M

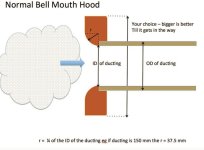

Some illustrations BobL provides in the FAQ - Dust Extraction (Practical Aspects) - well worth reading the entire FAQ!

Bill Pentz refers to using these in the section of his website on Tool Ducting under Dust hoods. At the Australian Woodwork Forum, there is a very active section on dust collection and one member, Bob Loss (BobL), posts extensively about improving dust ports and the connections to our machines. He is a big advocate of using bell shaped hoods to improve air flow for fine dust collection by as much as 20%. His principle thread on the topic where he discusses the four typical connections into a machine cabinet and then shows how to create bell shaped hoods in both 4" and 6" PVC pipe using a mold is here:

Improving machine cabinet dust ports

And the post within that thread where he shows his molding process is here:

Creating Bell Shaped Ports with a Mould

Two examples of the dust flow created with a bell mouth hood are illustrated by the sawdust flowing off of the wood being sanding in these two videos:

https://www.youtube.com/watch?v=xMlX1wavcWs

https://www.youtube.com/watch?v=xjtHCmR-N3M

Some illustrations BobL provides in the FAQ - Dust Extraction (Practical Aspects) - well worth reading the entire FAQ!