Hi,

You changed everything on me! I thought you were going to run the pipe parallel to the building so that you could filt the cyclone right next to the building which in turn would give you a little extra height. How tall are the side walls? That isn't the trash bin you are planning to use is it or have you already though how to seal it? That has to be airtight. In answer to your question I see no problem doing what you are asking about but we haven't tried that configuration ourselves so keep that in mind. I'll have dad take a look at this thread and add his thoughts if they are different than mine. Also do you mind if i move this thread to your other one so we can keep up with all the ideas that have been tossed around? It's fine if not.

Matt

Hi Matt, I'm fine with where you want to move things. I'm sorry if I put this thread in the wrong spot.

I'm still not sure what I'm going to do yet to be quite honest.

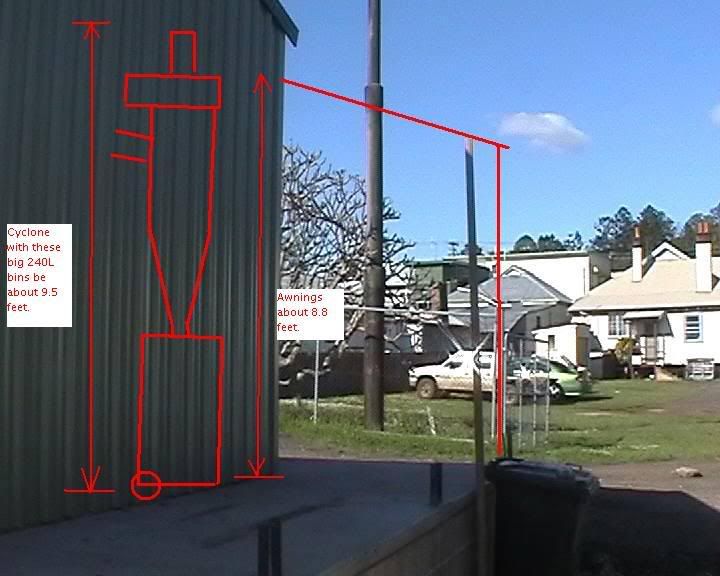

I'm told my awning can't be as high as I origionally wanted. Has to be about 8.8 feet high at most (give or take a bit. I'm not used to imperial)

And I've got my heart set on using these large garbage bins that are collected each Monday. It just sounds great being able to just wheel it out to the curb, without having to empty it myself. There big 240L things but are about 3.5 feet high unfortunately(and I shouldn't have any problem sealing them I'm thinking)

Problem is combined the heights going to be higher than the awning.

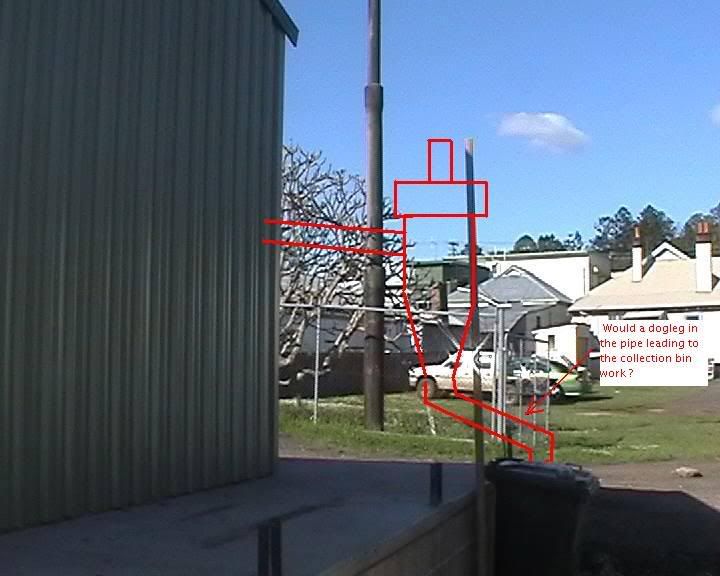

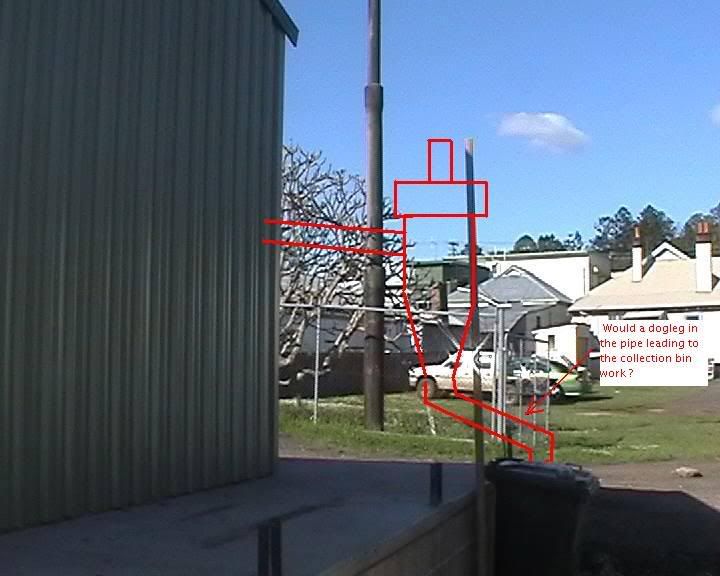

(I'll stick a heap of pictures here, should I fail to explain it properly

I know I don't make sense sometimes.)

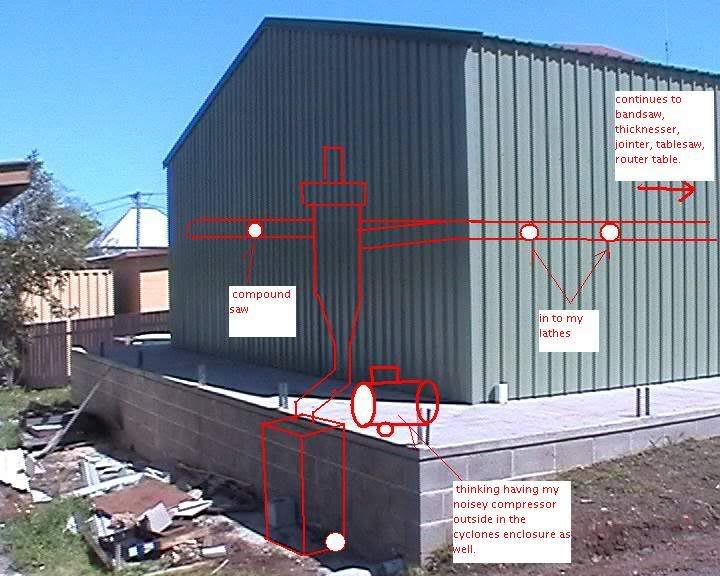

So, that why I was think this time bringing it all down, with the bin off the retainer wall. With the cyclone under the awnings cover. And with it as close to the edge of the retainer wall, I'll have more room to insulate (was thinking a couple of insulated filled independent walls to help dampen noise. Thinking it may reduce ducting as well since I'm at machine height already...and also thinking that I can have a longer straight from the machine before I hit a bend (unlike if I would have it it was right up against the shed wall ?..remember Bill saying that its important for good seperation ?)

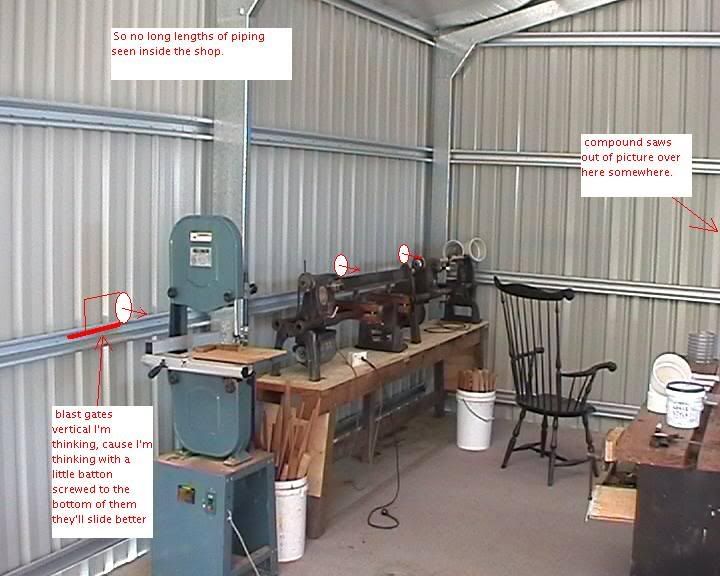

So end up with something like this ....with two main lengths of pipe running along the outside of the shed wall, turning in right on the machine, which I found appealing because it won't clutter the shops walls so much which I like to reserve for shelving and tools etc.

I don't know really whats best. Seems to be so many options. uno.