Hi, I'm curious what CFM #'s those of you that have done testing have gotten for your Clearvue 1800 systems. I've had a Clearvue 1800 for several years and tested it with several different workshop setups using a Dwyer 166 pitot tube and a digital manometer. I calculate using the raw inchesWC and a Dywer app that takes into consideration all the other variables like air temp/pressure/humidity and duct diameter. My shop is large (longest run ~30ft) with 11ft ceilings; I run 6" metal pipe with 6" drops, minimal flex tube, no 90 bends (all drops are on gradual wyes), meticulously sealed joints (smoke tested) etc. Even with this setup, I still get smaller CFM #'s than I'd expected when I bought my Clearvue. Overall static pressure for the system is 11.1.

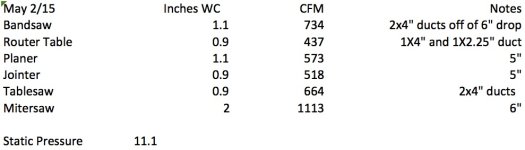

The attached file shows the CFM for my various machines and the final duct size (reduced right at the machine) Best run is the first drop from DC (and the only machine with a true 6" opening) which gives me ~1100CFM.

Outside of the CFM #'s, the system does keep the air clean (Dylos particle counter consistently has lower #'s in my shop than in my house).

The attached file shows the CFM for my various machines and the final duct size (reduced right at the machine) Best run is the first drop from DC (and the only machine with a true 6" opening) which gives me ~1100CFM.

Outside of the CFM #'s, the system does keep the air clean (Dylos particle counter consistently has lower #'s in my shop than in my house).