DEREK_PNW,

“Is enclosing the filters the best way to reduce the noise from the source?”…

I am convinced that mitigating noise from the filters is helpful, but may not go far enough. Since the rotating impeller is the source of the noise, mitigating the transmission of sound from the impeller and the impeller/filter transition should go even further in reducing noise. I have noticed that other cyclone makers offer a muffler that sets between the impeller and filters. They seem to claim around a 10 db reduction in sound with these mufflers (if I remember correctly).

A layer of Roxul, perhaps setting on the sound board you plan to use, could set atop the impeller housing (leaving space for air to circulate to the motor). Roxul that wraps the impeller housing could absorb some more sound. The Roxul could be held in place with some tape. My preference would be HVAC metal foil tape since the adhesive is strong and durable.

Likewise, wrapping the impeller/filter transition with Roxul may help more. This would be intended to mimic the muffler some manufacturers advocate.

Mitigating sound from the impeller and the impeller/filter transitions are steps that could be taken after the filter enclosure is completed. It may be that the filter enclosure would reduce the noise level sufficiently making these additional steps unnecessary. If not, then these additional steps could be employed.

“Any other thoughts on how to achieve this (providing for a path for escaping air from the enclosure)? “ …

Self-closing louvered vents require some pressure to open. If pressure within the filter stack enclosure is sufficient to open the dryer vent louvers, it indicates increased backpressure that could reduce performance. A second problem could be that the sound you are trying to capture and contain by the filter stack enclosure could escape the enclosure through the vents.

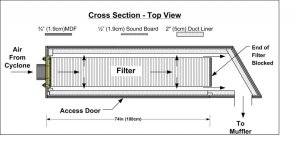

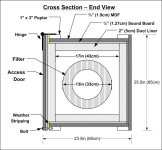

A different approach that allows the air to freely escape with minimal back pressure while capturing some sound would be to establish a channel through which escaping air flows. One or more sides of the enclosure could feature a large rectangular opening. A panel onto which the sound board and Roxul are affixed could then cover the rectangular opening. The channel would be established by using bushings to attach the panel, leaving a 2” to 3” gap between the enclosure and the panel. If the panel is oversized, some additional sound could be absorbed. For example the rectangular opening could be 18” x 42”. The panel could be 24” x 48” and attached, centered on the opening, with bushing that leave a 2” – 3” gap through which the air can escape. If this style of venting is applied to more than one side, air would encounter reduced resistance as it flows out of the filters.

Additional Remarks…

Since you mentioned filter maintenance, I would think that installing the filter enclosure on casters could allow full access to the filters. When it is time to clean the filters, the filter enclosure door can be opened and the filter enclosure rolled out of the way.

My approach to taming the CV1800 noise was a little different from your approach, but you may encounter the same problem I encountered. I enclosed the cyclone tower in a plywood enclosure. This left insufficient space for the filter stack when using the Clear Vue impeller/filter stack transition. I solved the problem by building a transition extension from MDF. This extension allowed the filter stack to set further away from the cyclone tower enclosure. The extension was a four sided box that connected to the impeller exhaust at one end and to the Clear Vue transition at the other end. Since your approach is to enclose the filters, your enclosure may encroach on the cyclone tower, so a similar transition extension may be required.

When I considered insulation, ROXUL mineral wool bat insulation was on my list but I elected to use UltraTouch Denim Insulation because I was persuaded that it offers better acoustical performance. I found it at my local home center. But more to the point, looking into the cost, availability, and acoustical specifications of various products may be worthwhile.