Corey Pelton

New member

Hello everyone!

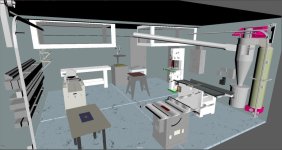

First post here! I've finally decided to step up my DC in my small garage shop (20x20x10). I'm happy to (soon) be a new owner of a CV1800. It will be delivered this coming Saturday. I had a couple questions about where you might layout the duct work for my particular setup? I chose this spot for the DC as its furthest away from the house proper and its where all my 240v lines begin. All of my machines are mobile, and are moved around as space and use necessitates. My biggest reason for needing a new DC was that my Minimax FS41E produces so many chips, my old DC couldn't even come close to handling it. It was a huge mess every time, and it made using the J/P combo machine a hassle. My other problem is that we do still park in the garage when I'm not working on a large project (which isn't often anymore) so I Tetris all the machines against the walls. Its a bit of a tight squeeze, but the cars can still fit.

So with the way my ducting will need to work, the drops will either be fairly short, mostly flex hose, or movable when necessary. I'm contemplating a pulley type system for pulling it up out of the way when not in use. That way I could get a bit longer drops. I think it could work, but might be more work than its worth. I have quite a few limits to what I can do, as I have 2 large overhead racks that hang toward the front of the garage. They block a good portion of my overhead space unfortunately. Plus the garage door itself makes for a bit of challenge for hanging the CV1800 to begin with. I'm planning to hang it quite a bit higher than the 96" recommendation. Most likely wherever the bracket will go without interfering with the garage door track. I have about 22" of head room above the 96", so it shouldn't be much problem. The higher I can get the starting run of pipe, the better.

Pardon my caveman 3D work, hah. It's definitely been a help to lay it out and see how it works, though. I've been checking out a lot of the Bill Pentz layouts, and various other posts on this forum and others. I have a general idea of where things should go, but I'd love to hear any particulars you fine folks might be able to give me.

Thanks for taking a look!

Corey

First post here! I've finally decided to step up my DC in my small garage shop (20x20x10). I'm happy to (soon) be a new owner of a CV1800. It will be delivered this coming Saturday. I had a couple questions about where you might layout the duct work for my particular setup? I chose this spot for the DC as its furthest away from the house proper and its where all my 240v lines begin. All of my machines are mobile, and are moved around as space and use necessitates. My biggest reason for needing a new DC was that my Minimax FS41E produces so many chips, my old DC couldn't even come close to handling it. It was a huge mess every time, and it made using the J/P combo machine a hassle. My other problem is that we do still park in the garage when I'm not working on a large project (which isn't often anymore) so I Tetris all the machines against the walls. Its a bit of a tight squeeze, but the cars can still fit.

So with the way my ducting will need to work, the drops will either be fairly short, mostly flex hose, or movable when necessary. I'm contemplating a pulley type system for pulling it up out of the way when not in use. That way I could get a bit longer drops. I think it could work, but might be more work than its worth. I have quite a few limits to what I can do, as I have 2 large overhead racks that hang toward the front of the garage. They block a good portion of my overhead space unfortunately. Plus the garage door itself makes for a bit of challenge for hanging the CV1800 to begin with. I'm planning to hang it quite a bit higher than the 96" recommendation. Most likely wherever the bracket will go without interfering with the garage door track. I have about 22" of head room above the 96", so it shouldn't be much problem. The higher I can get the starting run of pipe, the better.

Pardon my caveman 3D work, hah. It's definitely been a help to lay it out and see how it works, though. I've been checking out a lot of the Bill Pentz layouts, and various other posts on this forum and others. I have a general idea of where things should go, but I'd love to hear any particulars you fine folks might be able to give me.

Thanks for taking a look!

Corey