Chris Peisher

New member

Hello everyone. This is my first post here so thanks in advance for welcoming me to the community of cyclone owners. I purchased my cyclone setup from Ed, in person on New Years Day this last weekend. A big thanks to Ed for meeting me at 8 PM  I got a tour of the cyclone shop and his personal shop, got to see and hear his cyclone run and i was very impressed with how quiet he managed to get it. I hope i can enclose mine at some point to muffle the noise as well as he did...Any who, i digress...

I got a tour of the cyclone shop and his personal shop, got to see and hear his cyclone run and i was very impressed with how quiet he managed to get it. I hope i can enclose mine at some point to muffle the noise as well as he did...Any who, i digress...

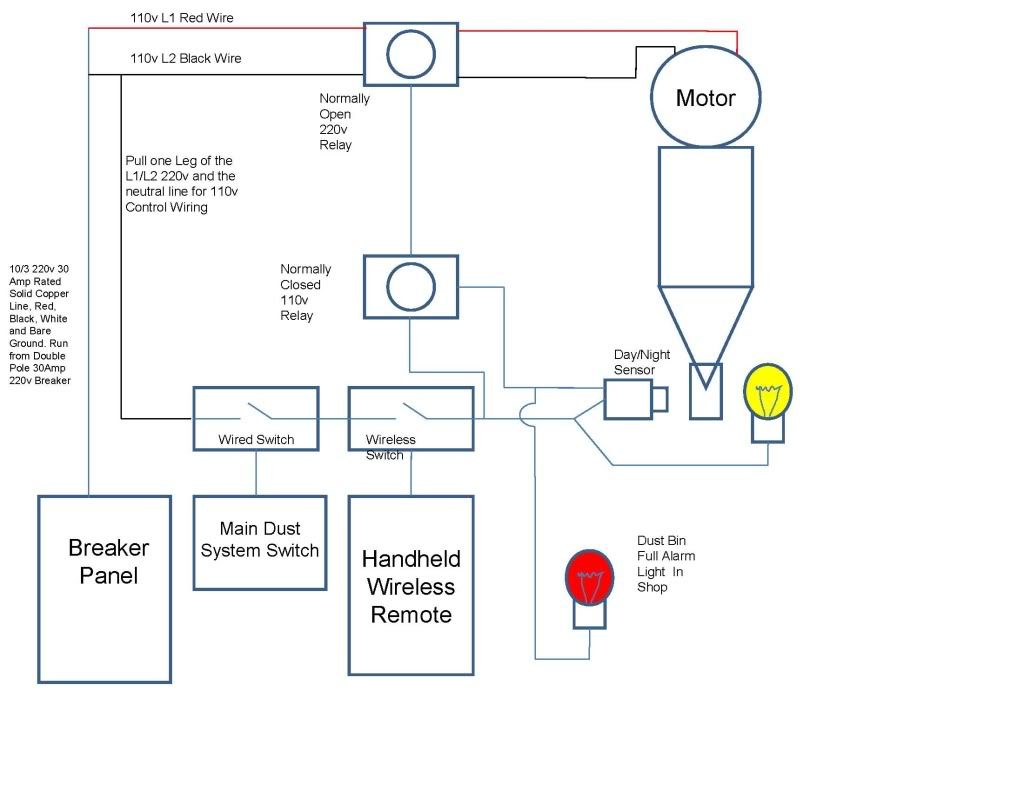

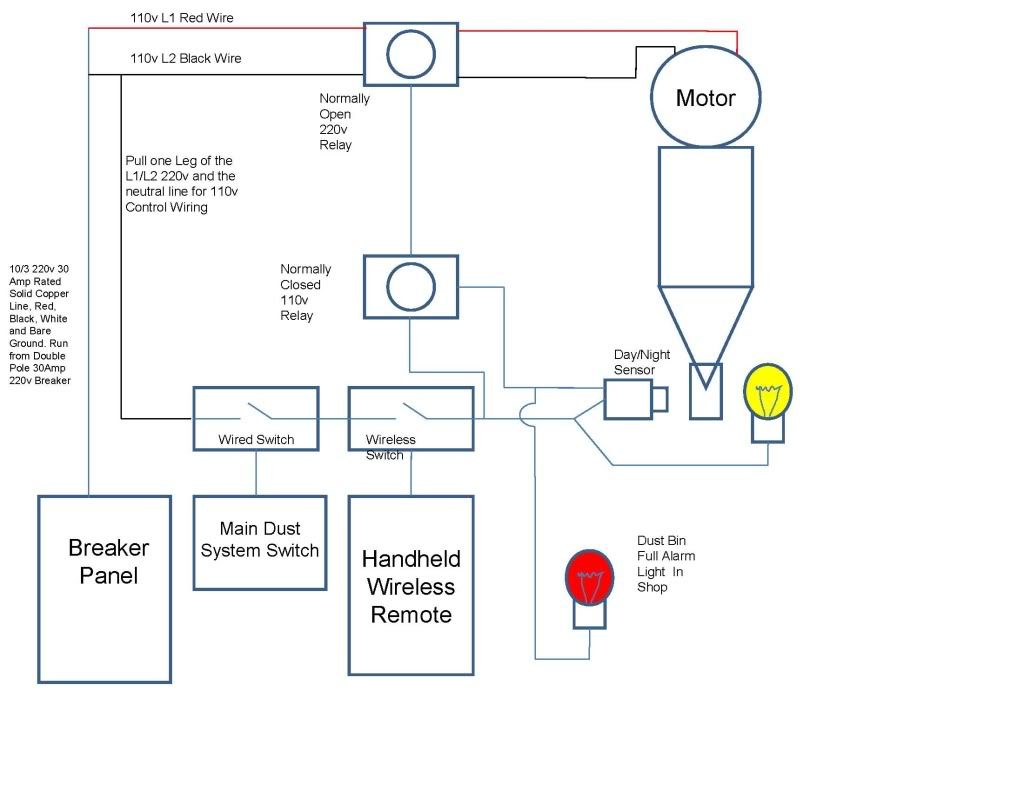

I have read alot of information recently about wiring the cyclones and the big mess people get into when they inadvertently forget to empty the dust bin and they fill their filter stack with shavings, dust, chips , etc. I want to do everything i can to avoid that entirely. I have included a picture of a wiring diagram i developed that accomplishes the goals below. I am not an electrician, but a mechanical engineer. I am submitting this here before i wire it so that i can get some good critical peer review before i attempt to wire all of this myself. Here is what i wanted this wiring scheme to accomplish...

1 - Have a master switch that would disable everything when i leave the shop.

2 - Have a remote switch that i carry on my tool belt to activate the DC from where ever i am in the shop.

3 - Have a dust bin full sensor that gives me a visual warning when the dust bin is full. I wear double hearing protection, ear plugs and over the ear protection as well. Addittionally, I sometimes work late at night in the garage, and i don't want an alarm to wake the kids who sleep one wall over.

4 - Have the same dust bin full sensor turn off the motor to prevent any chips, dust, or shavings from getting to the filter stack.

Please comment and let me know if you see any issues with what i have planned.

Thanks,

Chris

P.S. - The registration page cut the last letter, r, off my last name when i registered, can i get it added or can i change my user name to something else?

Wiring Diagram

Wiring Diagram

I have read alot of information recently about wiring the cyclones and the big mess people get into when they inadvertently forget to empty the dust bin and they fill their filter stack with shavings, dust, chips , etc. I want to do everything i can to avoid that entirely. I have included a picture of a wiring diagram i developed that accomplishes the goals below. I am not an electrician, but a mechanical engineer. I am submitting this here before i wire it so that i can get some good critical peer review before i attempt to wire all of this myself. Here is what i wanted this wiring scheme to accomplish...

1 - Have a master switch that would disable everything when i leave the shop.

2 - Have a remote switch that i carry on my tool belt to activate the DC from where ever i am in the shop.

3 - Have a dust bin full sensor that gives me a visual warning when the dust bin is full. I wear double hearing protection, ear plugs and over the ear protection as well. Addittionally, I sometimes work late at night in the garage, and i don't want an alarm to wake the kids who sleep one wall over.

4 - Have the same dust bin full sensor turn off the motor to prevent any chips, dust, or shavings from getting to the filter stack.

Please comment and let me know if you see any issues with what i have planned.

Thanks,

Chris

P.S. - The registration page cut the last letter, r, off my last name when i registered, can i get it added or can i change my user name to something else?

Wiring Diagram

Wiring Diagram

Attachments

Last edited: