Roadkill401

New member

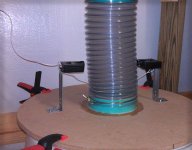

I am putting in the finishing touches for my ClearvuMax cyclone. I have two options for the chip bin.

I would prefer to use the semi transparent plastic 55gal drum that I had used with my old DC that was hooked up to a cyclone lid. As I don't have an orginal lid for this drum, I would have to build my own..

I know that this cyclone does create quite a bit of suction, and was thinking if I cut a board of MDF and put a rubber seal around the outside edge.. I was thinking of using something like a bicycle inner tube that will seal on the top lip edge of drum.

But I'd rather ask here for input first before trying something if it's known not to work, or if there is something far more easy or tested that I should do first.

thanks

Matt.

I would prefer to use the semi transparent plastic 55gal drum that I had used with my old DC that was hooked up to a cyclone lid. As I don't have an orginal lid for this drum, I would have to build my own..

I know that this cyclone does create quite a bit of suction, and was thinking if I cut a board of MDF and put a rubber seal around the outside edge.. I was thinking of using something like a bicycle inner tube that will seal on the top lip edge of drum.

But I'd rather ask here for input first before trying something if it's known not to work, or if there is something far more easy or tested that I should do first.

thanks

Matt.