This week I placed an order for a CV1800 w/16" Impeller to be shipped to me in Alaska. Knowing the speed at which the barges travel, I know I have a few weeks before it arrives, but that doesn't preclude the prep work.

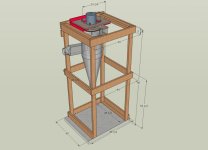

My intent is to build a free-standing stand, with an insulated "closet" built around it. I'm good on height because the shop has 9'-6" ceilings but I'd like to make the closet 3' deep (32" inside) by 4-6' long, if that's practical.

My thought is to mount the cyclone along the "short wall" with both the inlet and filters on the opposing end. With the inlet turned perpendicular to the "short wall", what is the minimum overall space required? I need to plan the free-standing stand and/or plan a larger closet if absolutely necessary.

Jim in Alaska

My intent is to build a free-standing stand, with an insulated "closet" built around it. I'm good on height because the shop has 9'-6" ceilings but I'd like to make the closet 3' deep (32" inside) by 4-6' long, if that's practical.

My thought is to mount the cyclone along the "short wall" with both the inlet and filters on the opposing end. With the inlet turned perpendicular to the "short wall", what is the minimum overall space required? I need to plan the free-standing stand and/or plan a larger closet if absolutely necessary.

Jim in Alaska