Hi all

I am close to placing an order for a new CV-1800... I gather from reading several of the posts here that for those venting back to the shop through filters there are three common practices for reducing noise:

I am committed to doing #1 and #2 above, but I am not certain whether there is any real motivation to also including #3... any comments? The downside I see for my specific application of adding the HVAC ducting is the additional space required to contain the duct inside the closet (ie larger enclosure means less shop space in my small garage shop!!).

Thanks in advance!!

Andy

I am close to placing an order for a new CV-1800... I gather from reading several of the posts here that for those venting back to the shop through filters there are three common practices for reducing noise:

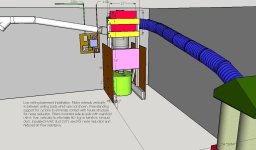

1) Building a closet/enclosure around the unit and soundproofing with something such as Roxul, or acoustic foam panels, etc.

2) Adding a folded baffle or chimney to the air return to muffle the sound coming from within the enclosure.

3) Adding a length (~8ft) of flexible insulated HVAC ducting between the blower exhaust and the input to the filters.

Have I missed anything important?2) Adding a folded baffle or chimney to the air return to muffle the sound coming from within the enclosure.

3) Adding a length (~8ft) of flexible insulated HVAC ducting between the blower exhaust and the input to the filters.

I am committed to doing #1 and #2 above, but I am not certain whether there is any real motivation to also including #3... any comments? The downside I see for my specific application of adding the HVAC ducting is the additional space required to contain the duct inside the closet (ie larger enclosure means less shop space in my small garage shop!!).

Thanks in advance!!

Andy