VermontDale

New member

I am reposting this message since I had it on the wrong forum.

Hi Clear Vue Cyclone owners,

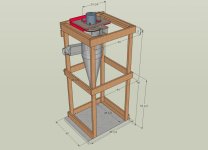

We have a shop is in a retirement community and are considering buying a CV1800. There are offices directly above the shop so the noise level is key.

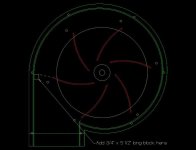

I built a Bill Pentz cyclone in 2002, so have some understanding of the issues but I need more data. (My son is now using the cyclone.)

To get an understanding of the noise levels I would first like to get noise readings with the CV1800 cyclone installed in a corner with no enclosure. It would be most useful if the filter were mounted vertically in the standard configuration. It seems to be common to make the noise measurement about 10 feet from the system. The ceiling in our shop is about 10 feet high.

It would be interesting to hear if people have measured different noise levels depending on the particular circumstances.

I have read the thread by John Samuel on the use of insulated air conditioning tubing to further reduce noise. Analyzing that will be my next step. (In fact, I used this technique successfully upon Bill's recommendation on the Bill Pentz cyclone in my old shop.)

Thanks,

Dale

Hi Clear Vue Cyclone owners,

We have a shop is in a retirement community and are considering buying a CV1800. There are offices directly above the shop so the noise level is key.

I built a Bill Pentz cyclone in 2002, so have some understanding of the issues but I need more data. (My son is now using the cyclone.)

To get an understanding of the noise levels I would first like to get noise readings with the CV1800 cyclone installed in a corner with no enclosure. It would be most useful if the filter were mounted vertically in the standard configuration. It seems to be common to make the noise measurement about 10 feet from the system. The ceiling in our shop is about 10 feet high.

It would be interesting to hear if people have measured different noise levels depending on the particular circumstances.

I have read the thread by John Samuel on the use of insulated air conditioning tubing to further reduce noise. Analyzing that will be my next step. (In fact, I used this technique successfully upon Bill's recommendation on the Bill Pentz cyclone in my old shop.)

Thanks,

Dale