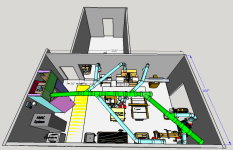

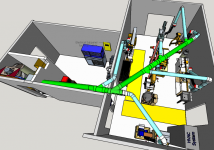

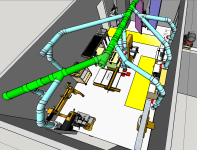

New shop, new dust collection installation... I need your input on the proposed layout for the shop, with emphasis on the dust collection ductwork layout.

This past year I moved to a retirement community in Huntsville, AL. We're now making serious upgrades to the community wood workshop. My part of the re-design is the dust collection system, which greatly impacts machine locations. I'd appreciate your suggestions on what I've drawn in SketchUp as our proposed layout. Some of you may recall that I installed a Clear Vue CV1800 in my home shop two years ago with great feedback from many of you here.

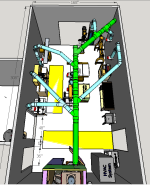

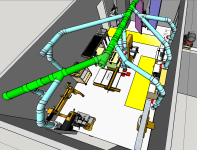

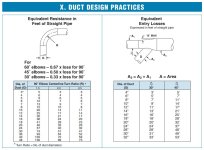

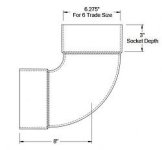

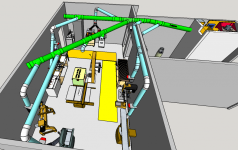

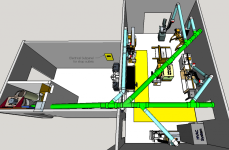

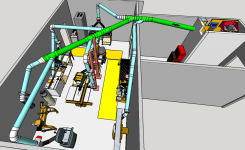

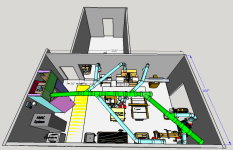

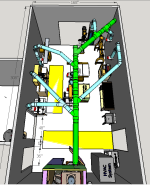

The dust collector for this multi-user shop will be the Clear Vue CVMAX (5HP, with Wynn Environmental filters) using 8" PVC SDR35 pipe for the main trunk line and 6" PVC thin wall S&D pipe (D-2729) for all the drops. The machines will be mostly Powermatic models. The plan is that we would not have more than two machines in operation at a given time, with only one machine operating at a time (i.e., blast gate open) on any given 6" drop. In this design, I've tried to keep the duct runs as straight as possible, with minimal turns and any 90-degree turns made gradually using 45-degree elbows with some straight pipe in between.

We will install the cyclone and filters in a sound isolation closet, but I have more design work yet to do on that. What you see in the drawings below is just a placeholder design for space planning. I'll make a separate post about the proposed sound insulation closet to ask for your suggestions when I've done some more work on that design.

Our shared use shop is small, about 14' wide by 26' long with 9.5' high ceiling. Fortunately, we have the use of a small side room for additional storage. The yellow rectangles shown on the floors mark 36" wide pathways that we want to keep clear. The pathway marked in front of the cyclone closet cannot have spinning blade tools along it because it is a regular pathway for the community's facilities employees - we want to keep them safe. Because of this "safety zone", it seemed became necessary to locate the cyclone on this wall and let the required 5' of straight pipe leading into the cyclone's intake run over top of this walkway space. (In an earlier draft of the layout, I tried placing the cyclone in a corner so we could run one trunk along the wall with 45-degree drops machines. But we had to abandon that layout when we were told to maintain this safety zone walkway.)

There are no 4" blast gates planned. All blast gates will be on the 6" pipe only to ensure someone doesn't throttle the air flow to the cyclone, not understanding that's what they are doing. (Remember, this is a shared use space and, while we will provide some training/certification to users, we have to plan on varying levels of understanding about the machines.)

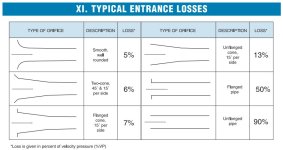

Also, I should add that 1) all the machines will be moveable on casters, either locking or retractable. And 2) For the larger volume dust creators, we plan to run solid pipe as close to the machine's dust port(s) as possible. My goal is to have no more than 4' of flex duct connecting the larger machines, but I'm sure we'll end up with greater lengths here and there. And 3) I've not sorted out dust hoods/shrouds, and we will need them for the sanding machines, scroll saw, router table, etc. I will likely experiment with some bell mouth hoods for various pipe ends connections, per the Australian Woodworkers Forum - anyone worked with these?

I welcome and will appreciate your suggestions. Please ask whatever questions you like, as well.

This past year I moved to a retirement community in Huntsville, AL. We're now making serious upgrades to the community wood workshop. My part of the re-design is the dust collection system, which greatly impacts machine locations. I'd appreciate your suggestions on what I've drawn in SketchUp as our proposed layout. Some of you may recall that I installed a Clear Vue CV1800 in my home shop two years ago with great feedback from many of you here.

The dust collector for this multi-user shop will be the Clear Vue CVMAX (5HP, with Wynn Environmental filters) using 8" PVC SDR35 pipe for the main trunk line and 6" PVC thin wall S&D pipe (D-2729) for all the drops. The machines will be mostly Powermatic models. The plan is that we would not have more than two machines in operation at a given time, with only one machine operating at a time (i.e., blast gate open) on any given 6" drop. In this design, I've tried to keep the duct runs as straight as possible, with minimal turns and any 90-degree turns made gradually using 45-degree elbows with some straight pipe in between.

We will install the cyclone and filters in a sound isolation closet, but I have more design work yet to do on that. What you see in the drawings below is just a placeholder design for space planning. I'll make a separate post about the proposed sound insulation closet to ask for your suggestions when I've done some more work on that design.

Our shared use shop is small, about 14' wide by 26' long with 9.5' high ceiling. Fortunately, we have the use of a small side room for additional storage. The yellow rectangles shown on the floors mark 36" wide pathways that we want to keep clear. The pathway marked in front of the cyclone closet cannot have spinning blade tools along it because it is a regular pathway for the community's facilities employees - we want to keep them safe. Because of this "safety zone", it seemed became necessary to locate the cyclone on this wall and let the required 5' of straight pipe leading into the cyclone's intake run over top of this walkway space. (In an earlier draft of the layout, I tried placing the cyclone in a corner so we could run one trunk along the wall with 45-degree drops machines. But we had to abandon that layout when we were told to maintain this safety zone walkway.)

There are no 4" blast gates planned. All blast gates will be on the 6" pipe only to ensure someone doesn't throttle the air flow to the cyclone, not understanding that's what they are doing. (Remember, this is a shared use space and, while we will provide some training/certification to users, we have to plan on varying levels of understanding about the machines.)

Also, I should add that 1) all the machines will be moveable on casters, either locking or retractable. And 2) For the larger volume dust creators, we plan to run solid pipe as close to the machine's dust port(s) as possible. My goal is to have no more than 4' of flex duct connecting the larger machines, but I'm sure we'll end up with greater lengths here and there. And 3) I've not sorted out dust hoods/shrouds, and we will need them for the sanding machines, scroll saw, router table, etc. I will likely experiment with some bell mouth hoods for various pipe ends connections, per the Australian Woodworkers Forum - anyone worked with these?

I welcome and will appreciate your suggestions. Please ask whatever questions you like, as well.