In many discussions about enclosing the DC in a closet etc the topic of providing moving air around the motor comes up. I'm struggling with a solution for this and wonder just how critical is this? Would just a vent suffice? To achieve moving air I'm going to have to bring outside air into the closet and then into the larger shop space. Simple in theory but I'm limited on where I introduce the outside air from so It will be pretty warm to begin with in the heat of our Texas summers. Heck it's October and were having temps in the 90's!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are you cooling the motor?

- Thread starter gstuartw

- Start date

Stuart,

You can start with a pair of vents into your closet from interior space with one near the base and one near the top to allow natural convection to expel the hotter air from the top of the closet. If the heat build up becomes too much, you can add a fan inside the lower vent to force more air through the closet -- stop by your local HVAC service company and see if they have any ol furnace fans they's be willing to part with since they are quiet and move plenty of air (some are even multi-speed).

You can start with a pair of vents into your closet from interior space with one near the base and one near the top to allow natural convection to expel the hotter air from the top of the closet. If the heat build up becomes too much, you can add a fan inside the lower vent to force more air through the closet -- stop by your local HVAC service company and see if they have any ol furnace fans they's be willing to part with since they are quiet and move plenty of air (some are even multi-speed).

Stuart,

You can start with a pair of vents into your closet from interior space with one near the base and one near the top to allow natural convection to expel the hotter air from the top of the closet. If the heat build up becomes too much, you can add a fan inside the lower vent to force more air through the closet -- stop by your local HVAC service company and see if they have any ol furnace fans they's be willing to part with since they are quiet and move plenty of air (some are even multi-speed).

I'm considering that solution Robert. Here are my thoughts:

I'm exhausting the 1800 directly outside so in times of extreme heat of cold temps I'll want to have a source of makeup air other than an open door or window. The solution I'm considering is to place a vent directly above the motor with insulated duct running from that through the attic to a soffit vent outside the shop. A second vent mounted along the bottom of a wall of the DC closet will pull the outside make up air past the motor and into the shop. That of course will create one more penetration of the DC closet walls that are designed to contain the noise of the 1800.

An additional wrinkle is that during those extreme temps I will likely exhaust the 1800 into the Wynn filter stack in the DC closet. In that case I'll need to return the air from the closet into the shop. I will of course have the two vents described in the previous paragraph. I guess I could close the vent above the motor so as not to vent outside. The other vent would then allow air from the filters to go back to the shop. Given the vent will be 9' below the motor the cooling I hope to achieve will be compromised.

The solution might be to instead close the lower vent and have a way of rerouting the upper vent to go back into the shop. It would be easy to create a break in the flex vent in the attic and attach it to a ceiling vent in the shop. In doing so I will be reducing the noise transmission by moving the air through 15-20 feet of insulated duct.

Thoughts?

Exhausting filtered air in the closet and returning it through a large vent low to the floor will promote some cooling (it would be better if you built a plenum in the wall between a pair of studs and pulled air from the top of the closet out through a vent near the floor in the outside of the closet wall into the shop). If you rely on convection through several feet of HVAC duct from the closet to the exterior, I doubt you will get much flow without a fan to provide a forced flow.

Exhausting filtered air in the closet and returning it through a large vent low to the floor will promote some cooling (it would be better if you built a plenum in the wall between a pair of studs and pulled air from the top of the closet out through a vent near the floor in the outside of the closet wall into the shop).

In the case of producing make up air when using filters I've simplified my most recent plan.

One change is that I do not need to provide the outside air from a lengthy hvac duct that pulls from the soffit vent as suggested. I already have a duct attached to the outside. That would be the very same duct I'd be expelling air from when venting air outside. When using the filters I'd just disconnect the duct section from the 1800 impeller housing. Then I'd attach flex duct from the impeller housing to the filter stack.

Another change is to do what you have suggested and take air from high up and force it down through a plenum and out into the shop. At this point my closet walls are complete. The stud cavities are stuffed with sound deadening insulation and the sheet rock covered with 1/2" neoprene. I'll build a surface mount plenum on one of the walls to achieve the same result.

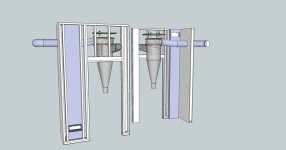

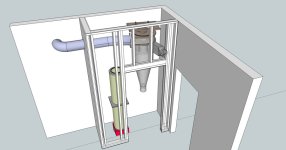

SketchUp drawings included should illustrate this…

This shows the closet as it stands so far…well the walls are complete but hidden to show the interior equipment. Exhaust from the DC is sent directly outside.

This double view is to illustrate the plenum I'd build to send makeup air back into the main room from the closet.