My Basement is unique or maybe not. I have 84" of head room to the floor joists above. I have had to repair and support my cinder block wall because clay was used for the back fill material and it had bowed in. The wall has been repaired; the exterior excavated and new weep holes and drain tiles installed and properly backfilled with #1 washed stone. Inside there are 2 X 5 beams anchored to the footings tho the floor joist above all along its length and new drain tiles leading to a sump crock installed. Across the bottom of the 2x10 floor joist 1/4 inch x 4 inch plates across three joist were installed to keep the beam anchored at the top.

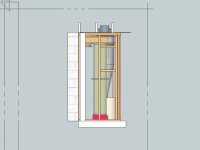

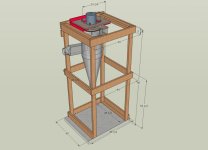

Here is what I would like to do. At the second and third joist cavity hang my CV1800 between two 1/4x4X50 inch plates 48 inches apart. I have these 5 foot 1 inch square tubes with 1/8 in walls that would hold everything no problem.

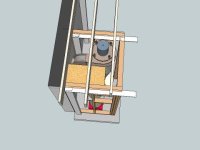

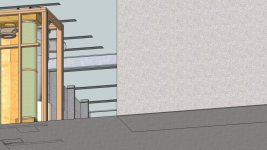

My included .jps should give you an idea of what this is all about. The hangar tubes are not drawn in just yet. I do think I could leave out the crowns, anchor the wall to to the cinder block and there by not attaching to the floor above. There will be a standard 2' 6" door in the rough opening.

Any Comments are welcome. There is also a glass block window to the right of the closet and the reason I have not made it larger. This is my first choice for a locatiion and if it just won't work its back to Sketchup the free program from Google and a great program for woodworkers and a bunch of more moving of my shop.

Tom

Here is what I would like to do. At the second and third joist cavity hang my CV1800 between two 1/4x4X50 inch plates 48 inches apart. I have these 5 foot 1 inch square tubes with 1/8 in walls that would hold everything no problem.

My included .jps should give you an idea of what this is all about. The hangar tubes are not drawn in just yet. I do think I could leave out the crowns, anchor the wall to to the cinder block and there by not attaching to the floor above. There will be a standard 2' 6" door in the rough opening.

Any Comments are welcome. There is also a glass block window to the right of the closet and the reason I have not made it larger. This is my first choice for a locatiion and if it just won't work its back to Sketchup the free program from Google and a great program for woodworkers and a bunch of more moving of my shop.

Tom