David Klotz

New member

Folks-

I am the new owner a Mini CV 06. It is paired with a brand new Ridgid 11 amp shop vacuum, equipped with a HEPA filter. Mods to the vacuum include:

1) drain outlet cap threads sealed with plumber's tape;

2) weather stripping added to top of bin for a better seal (substantial improvement in suction);

3) Ridgid diffuser/muffler added, stuffed with stel wool.

The run from the cyclone to the vacuum inlet is extremely short, less than a foot.

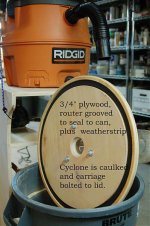

My problem is that the suction is so great the container beneath the cyclone collapses. My first container was a Rubbermaid Brute 20 gallon trash container. The top was fabricated from 3/4" cabinet grade birch plywood, router grooved and weather stripped on the underside for a tight seal to the trash can. The cyclone was attached with carriage bolts, and sealed with silicone caulk.

Even at steady state, no load running, the trash can would slightly collapse. Add a hose full of sawdust, and the can would seriously collapse, and compromise the seal.

So, I scrapped the Rubbermaid trashcan, and tried a 20 gallon, "heavy duty" galvanized steel trashcan. Then, I fabricated a second top for that, and fired it up. Same bad result. Any suction load, and the can would resoundingly collapse.

Any suggestions on what I can do? I'd prefer not to buy a 55 gallon drum. Too heavy to empty, and too heavy to trundle around the shop. Also, I have already made up a rolling cart for the cyclone and vacuum.

Any input would be most appreciated.

Pics attached....

Thanks-David Klotz

I am the new owner a Mini CV 06. It is paired with a brand new Ridgid 11 amp shop vacuum, equipped with a HEPA filter. Mods to the vacuum include:

1) drain outlet cap threads sealed with plumber's tape;

2) weather stripping added to top of bin for a better seal (substantial improvement in suction);

3) Ridgid diffuser/muffler added, stuffed with stel wool.

The run from the cyclone to the vacuum inlet is extremely short, less than a foot.

My problem is that the suction is so great the container beneath the cyclone collapses. My first container was a Rubbermaid Brute 20 gallon trash container. The top was fabricated from 3/4" cabinet grade birch plywood, router grooved and weather stripped on the underside for a tight seal to the trash can. The cyclone was attached with carriage bolts, and sealed with silicone caulk.

Even at steady state, no load running, the trash can would slightly collapse. Add a hose full of sawdust, and the can would seriously collapse, and compromise the seal.

So, I scrapped the Rubbermaid trashcan, and tried a 20 gallon, "heavy duty" galvanized steel trashcan. Then, I fabricated a second top for that, and fired it up. Same bad result. Any suction load, and the can would resoundingly collapse.

Any suggestions on what I can do? I'd prefer not to buy a 55 gallon drum. Too heavy to empty, and too heavy to trundle around the shop. Also, I have already made up a rolling cart for the cyclone and vacuum.

Any input would be most appreciated.

Pics attached....

Thanks-David Klotz