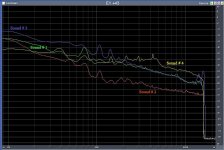

Freq. Analysis

Freq. Analysis

jgveill,

My plan is to do just that, and also try some of the noise reduction items we've been discussing in this topic. I have an old Win95 Pentium II box I can use, along with one of those awful microphones that came with computers of that era. I have no idea how good, or bad, the microphone is, but schemed to generate a tone sweep, put it on a CD, and play it through some decent speakers. That should give me a fair idea, with the GSpec spectrum software PWH Chris suggested. Assuming the mic is decent, then I should be able to get the wav and/or MP3 file.

Assuming Ed agrees its OK, I'd have no problem posting it, but am aware competitors may use it against him, so I will defer to his wishes. We can cross that bridge when we get to it. My CV 1800 is still in boxes, so I cannot supply an audio file today. I must complete some other projects prior to starting its assembly, so I don't foresee being able to supply the information until sometime in September, at the earliest.

As FORTRAN is the only foreign language I once spoke, all I can say is your English is bound to be much better than any attempt I might make in your native tongue, so no need for apologies.

Ultimately, Ed and others are quite correct, that the most effective noise reduction is going to be putting the unit in an insulated closet. Please note the installation in Ed's new shop, in the photo gallery section. If you haven't gone through that yet, there are a lot of good ideas, for noise control, assembly tips, and novel solutions to various challenges that inevitably crop up in custom projects. Thus I recommend you spend some time and go through the photos and comments there, if you haven't already.

Regards,

DWD

Freq. Analysis

jgveill,

My plan is to do just that, and also try some of the noise reduction items we've been discussing in this topic. I have an old Win95 Pentium II box I can use, along with one of those awful microphones that came with computers of that era. I have no idea how good, or bad, the microphone is, but schemed to generate a tone sweep, put it on a CD, and play it through some decent speakers. That should give me a fair idea, with the GSpec spectrum software PWH Chris suggested. Assuming the mic is decent, then I should be able to get the wav and/or MP3 file.

Assuming Ed agrees its OK, I'd have no problem posting it, but am aware competitors may use it against him, so I will defer to his wishes. We can cross that bridge when we get to it. My CV 1800 is still in boxes, so I cannot supply an audio file today. I must complete some other projects prior to starting its assembly, so I don't foresee being able to supply the information until sometime in September, at the earliest.

As FORTRAN is the only foreign language I once spoke, all I can say is your English is bound to be much better than any attempt I might make in your native tongue, so no need for apologies.

Ultimately, Ed and others are quite correct, that the most effective noise reduction is going to be putting the unit in an insulated closet. Please note the installation in Ed's new shop, in the photo gallery section. If you haven't gone through that yet, there are a lot of good ideas, for noise control, assembly tips, and novel solutions to various challenges that inevitably crop up in custom projects. Thus I recommend you spend some time and go through the photos and comments there, if you haven't already.

Regards,

DWD