kinghong1970

New member

Sorry for so many questions...

i rarely touch anything over 12v...

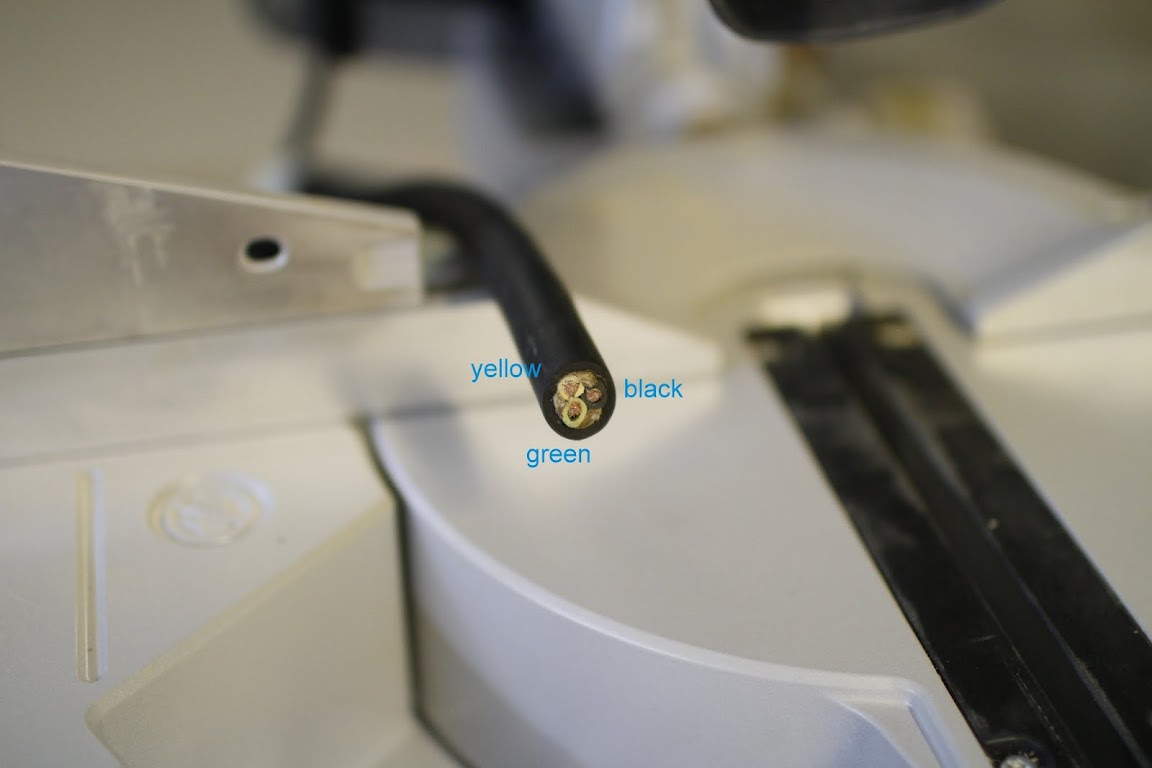

anyways, i am at the point where i am connecting the wire to the motors and i'm confused... motor once the panel was removed, looks like this... no labels, all the same yellow color and all so confusing to me... hahaha

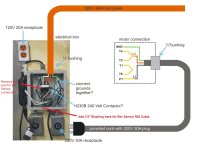

so i have 3 leads to connect... but have no clue how this translates to any of this:

nor do i know where to connect it to:

can someone teach me, as if you're teaching a 5 year old... yellow goes where, black goes where and green goes where?

i am getting an electrician to come and re-check my connections and mount/connect the electrical box...

thanks in advance,

Al

i rarely touch anything over 12v...

anyways, i am at the point where i am connecting the wire to the motors and i'm confused... motor once the panel was removed, looks like this... no labels, all the same yellow color and all so confusing to me... hahaha

so i have 3 leads to connect... but have no clue how this translates to any of this:

nor do i know where to connect it to:

can someone teach me, as if you're teaching a 5 year old... yellow goes where, black goes where and green goes where?

i am getting an electrician to come and re-check my connections and mount/connect the electrical box...

thanks in advance,

Al